Acting as sound diffusers, the grooves on the PET panel scatter incoming sound waves, thereby minimizing echoes, enhancing speech clarity, and fostering a more harmonious acoustic atmosphere. Furthermore, the PET material itself offers sound absorption capabilities, which further mitigates sound reflections. These panels are widely utilized in a range of environments, such as offices, conference rooms, auditoriums, home theatres, and restaurants. Their versatility allows for application on both walls and ceilings, tailored to the specific acoustic requirements of the area. The choice of PET material is often motivated by its environmentally friendly attributes, as it is recyclable and reusable.

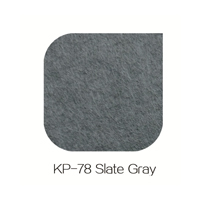

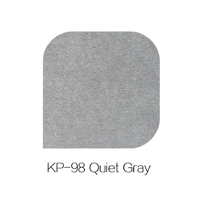

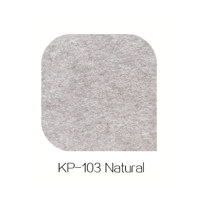

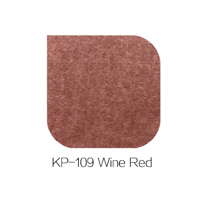

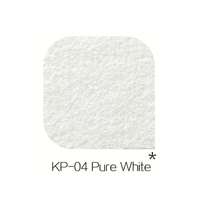

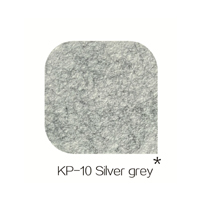

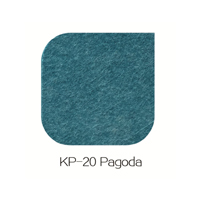

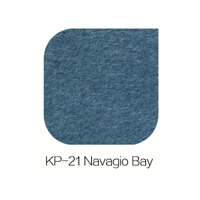

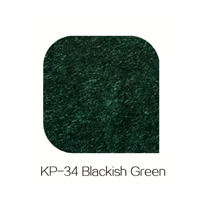

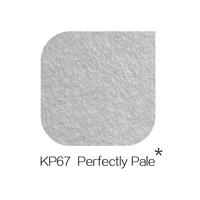

By transforming plastic waste into functional and visually appealing interior solutions, PET grooved acoustic panels support sustainable design initiatives. Available in a variety of colors and finishes, these panels can be customized to align with the interior design and decor of the space, with grooved patterns designed to achieve a particular visual effect.

| Designer | Sound Absorption Test Method | Noise Reduction Coefficient (NRC) | Dimensions | Fire Test Result | Composition | Weighted Alpha Coefficient (αw) | Sound Absorption Class |

|---|---|---|---|---|---|---|---|

| Woven Image | AS ISO 354: 2006 (R2016), ASTM C423 – 17, AS ISO 11654: 2002 (2016) | Direct fix: 0.30, 20mm air gap: 0.50, 50mm air gap: 0.70., Achieves an NRC of 0.75 with a 18mm acoustic backing | Length: 2440mm,Width: 1220 mm: Thickness:9/12 mm | ASTM E84 Unadhered: Class 1 or A, ISO 9705: Group 1, BS EN 13501.1: Classification B – s1, d0 | 100% PET (51% recycled) | Direct fix: 0.20 (H), 20mm air gap: 0.35 (MH), 50mm air gap: 0.60, (MH). Achieves an aw of 0.75 with a 18mm acoustic backing | E (Direct fix), D (20mm air gap), C (50mm air gap), BS EN 13501.1: Classification B – s1, d0 |